Credit: Visual China

(资料图)

(资料图)

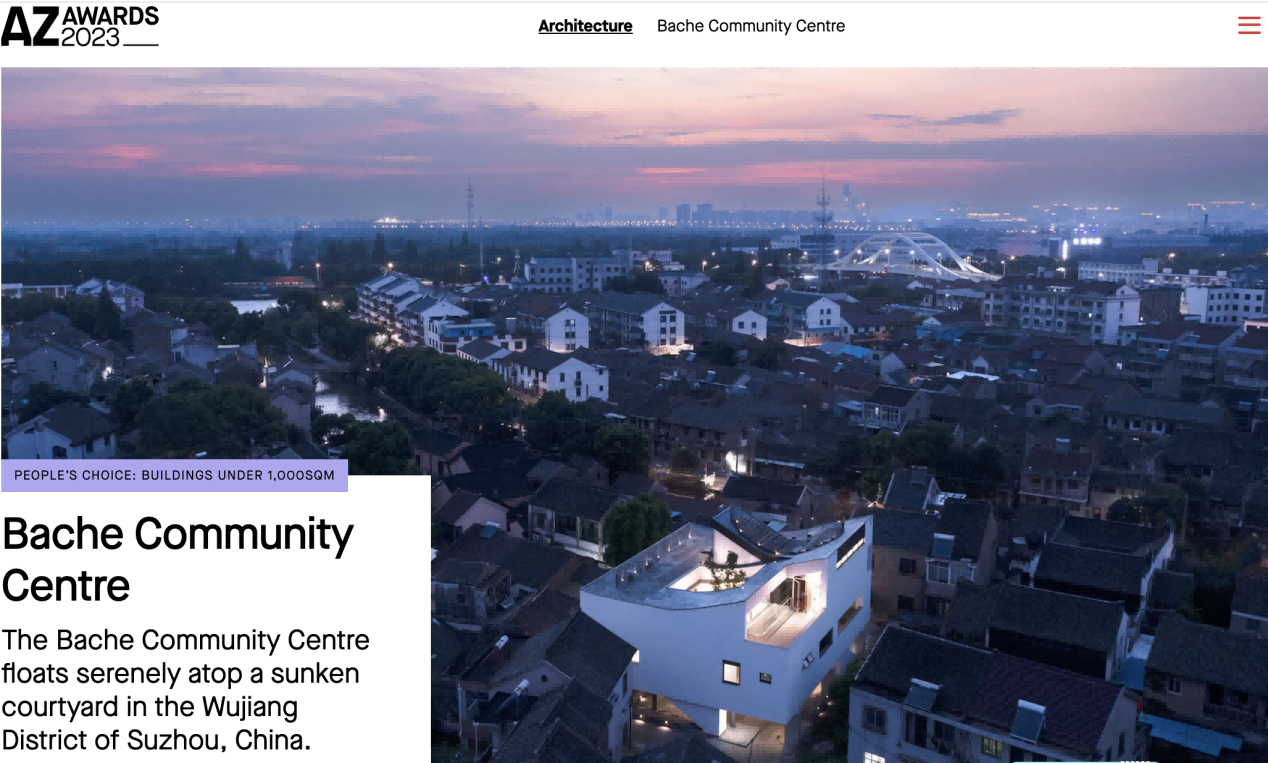

BEIJING, July 3 (TiPost) – The 10-year construction of German chemical giant BASF’s Innovation Campus Shanghai, Phase III project was officially completed last Wednesday, with a price tag of 280 million euros.

Prior to the inauguration of Phase III, the campus had already become the company’s largest research and development base in the Asia-Pacific region. With two expansion projects completed in 2015 and 2019, the addition of Phase III further solidifies its position. The Phase III project consists of two state-of-the-art research and development buildings dedicated to advancing chemical research programs and driving the development of sustainable solutions.

Jeffrey Lou, Chairman and President of BASF Greater China, emphasized that the Phase III project will prioritize innovative materials processes and the integration of advanced digitalization and automation capabilities.

Furthermore, BASF is actively increasing its investment in production facilities to cater to the growing demand in the Chinese market. Notably, the acrylic acid production complex at the BASF Zhanjiang Verbund site broke ground in March of this year. The chemical giant plans to invest up to 10 billion euros in this site by 2030.

Despite the heightened uncertainty in the global economy, BASF maintains stable profit expectations for 2023, with a sales target of 84 to 87 billion euros this year.

The company has made investments of more than 13 billion euros in China, establishing over 30 production sites. Its sales in Greater China have experienced substantial growth, rising from 7.3 billion euros in 2017 to 11.6 billion euros in 2022.

On September 15, 2022, BASF and China National Chemical Engineering Co., Ltd. signed a partnership framework agreement in Zhanjiang, Guangdong province, to jointly advance the construction of BASF Zhanjiang Verbund site. This ambitious investment amounts to 10 billion euros, equivalent to five Tesla Gigafactories, and stands as BASF’s largest foreign investment to date. Anticipated to be fully completed by 2030, the Zhanjiang site will become the company’s third-largest integrated production base worldwide.

The site has already witnessed the successful completion and operation of its first engineering plastics production unit in September 2022. Another unit focusing on thermoplastic polyurethane is set to commence operations soon. “Our aim is to transform the Zhanjiang site into a beacon project within the global chemical industry, serving as the safest, most intelligent, and most sustainable verbund site,” said Lou.

The establishment of an innovation center in Shanghai is BASF’s latest move to further enhance local innovation capabilities in China. With the large investment in the Innovation Campus Shanghai, the company aims to foster open innovation by collaborating with Chinese universities and research institutes, while also engaging in collaborative innovation with customers to facilitate the industrialization of the company’s research findings.

BASF has forged strategic partnerships with institutions such as the Chinese Academy of Sciences, the National Natural Science Foundation of China, Tsinghua University, Fudan University, and South China University of Technology, among others. Through these collaborations, the company aims to establish a robust innovation ecosystem in Asia. Lou highlighted that one crucial role of the Innovation Campus Shanghai is to facilitate the commercialization of Chinese research accomplishments.

According to Lou, China’s innovation landscape is becoming more welcoming, presenting numerous opportunities for multinational corporations to operate in a transparent, international, and rule-based manner.